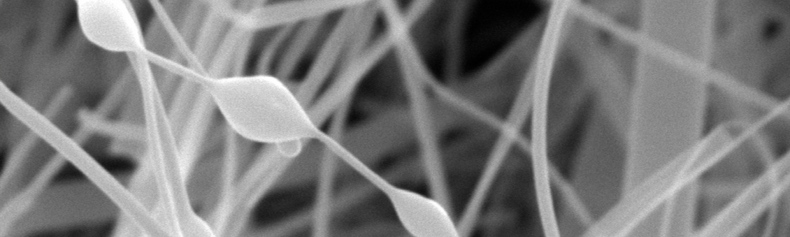

The NUENEX technology enables the production of nanofibers from a set of polymers. The nanofibers can be used alone or NUENEX enables their combination with desired active molecules (i.e., drugs, nanoparticles, functional additives).

The selection of a polymeric matrix is dependent on the final application and can be selected from a wide range of polymers:

- Natural polymers – the NUENEX technology is used for the preparation of nanofibers from a range of natural polymers, such as collagen, hyaluronic acid, chitosan, alginate, cellulose, lignin, or pullulan. Products from these polymers show excellent biocompatibility, low environmental impact. and are ideal for applications in cosmetics, food, feed, medical devices, or biomedical products.

- Biodegradable polyesters – NUENEX is compatible with most biodegradable polymers, such as polymers based on polylactic acid, polycaprolactone, polyhydroxybutyrate and polyglycerol sebacate. NUENEX enables the formation of active-molecule enriched nanofibers from these polymers, which enables long-term release of active molecules. Polyester-based membranes manufactured by the NUENEX technology enable the regulation of active molecule release ranging from days to months, which makes the system preferrable for medical devices, long-term drug delivery, or advanced packaging applications.

- Medical synthetic polymers – besides biodegradable polyesters, the NUENEX technology is compatible with a wide range of standard medical polymers. Starting from polyurethanes and polyamides for medical device applications, through excipients for drug formulations based on polyethylene glycol, polyvinyl alcohol and polyvinylpyrrolidone, to high performance polymers, such as stimuli responsive polymers or hyperbranched polymers. NUENEX enables the harvesting of their potential in drug delivery, nanoparticle-enriched products, or microporous barrier membranes.

- Industrial synthetic polymers – NUENEX is compatible with most industrial polymers (except polypropylene and polyethylene). The nanofibrous membranes can be based on polyurethanes, polyesters, polyamides, polysulfones, polyacrylates, polyacrylonitrile, polyvinyl butyral and fluorinated polymers. Either alone or combined with the nanoencapsulation of functional additives, they may be the backbone of advanced filtration, catalytic and barrier membranes.

Such versatility of the NUENEX technology enables the processing of most available polymers. If you are interested in a particular polymer and in exploring its compatibility with NUENEX, please do not hesitate to contact us.

The final polymeric nanofiber matrices produced by NUENEX are available in the form of sheets/membranes or microparticles with nanofibrous morphology. Our team of dedicated researchers is prepared to assist you with the adaptation of the system to your particular application.